Skip to main content

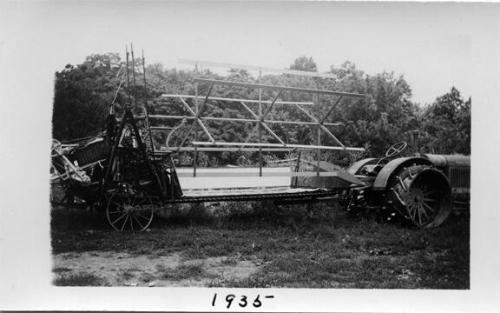

Threshing Time is a replica of an actual threshing outfit, which I worked with in the late 1940s. It consists of a 1929 McCormick-Deering thresher powered by a 1929 McCormick-Deering model 15-30 tractor. The truck, a 1930 Dodge was not part of the actual outfit, but is similar to the one my father owned a few years earlier. The bundles of grain were pitched from the wagon into the feeder of the thresher, where they were conveyed through the bundle cutter into the threshing mechanism where the grain was separated from the straw and chaff. The grain then came out of the grain spout while the straw was blown out the blower pipe located on top of the rear of the machine into a stack or barn or shed. The grain might be bagged, or in some cases it was let run directly into the truck or wagon.

Artist

Lavern Kelley

(1928 - 1998)

Threshing Time

Date1991

DimensionsOverall: 13 × 21 1/4 × 53 5/8 in. (33 × 54 × 136.2 cm)

Object numberN0140.1994

Credit LineCollection of the Fenimore Art Museum. Museum Purchase

Photograph by Richard Walker

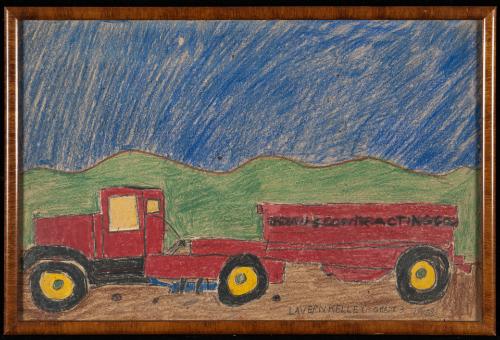

Label TextLavern Kelley started carving at the age of seven while recuperating from an appendectomy. He continued to carve for himself throughout his life while running the family farm. It was not until 1975 that several antique dealers in the Cooperstown/Oneonta area showed interest in his work and, in 1986, he became artist-in-residence at Gallery 53 in Cooperstown. Kelley was inspired by his surroundings and carved whole farmyard environments: trucks, tractors, equipment, farmers, and scenes of regular farm activity such as can be seen in Threshing Time.Threshing Time is a replica of an actual threshing outfit, which I worked with in the late 1940s. It consists of a 1929 McCormick-Deering thresher powered by a 1929 McCormick-Deering model 15-30 tractor. The truck, a 1930 Dodge was not part of the actual outfit, but is similar to the one my father owned a few years earlier. The bundles of grain were pitched from the wagon into the feeder of the thresher, where they were conveyed through the bundle cutter into the threshing mechanism where the grain was separated from the straw and chaff. The grain then came out of the grain spout while the straw was blown out the blower pipe located on top of the rear of the machine into a stack or barn or shed. The grain might be bagged, or in some cases it was let run directly into the truck or wagon.

On View

Not on view