Skip to main content

After the carefully worked, thinned-out plank has been soaked to saturate the wood cells with moisture and steam heat has been applied to soften the lignin that binds the cells together, the plank can be bent on the three kerfs to create the four sides of the container. The fourth corner was in this case sewn with a sinew cord, the usual method in older bent containers from the early 19th century and before. An experienced carver removed the right amount of wood from just the right places so that the corners could bend efficiently and the inside of the rim could meet precisely at the corners. The interplay of dynamic curves in the shapes of the sides make this process much more challenging than the appearance of the refined finished product might suggest. (From the Catalog of the Thaw Collection of American Indian Art, 2nd ed.)

ProvenanceMorning Star Gallery, Santa Fe, New Mexico

BibliographyVincent, Gilbert et al. Art of the North American Indians: The Thaw Collection. Cooperstown, New York: Fenimore Art Museum, 2000, p.335.

Fognell, Eva and Alexander Brier Marr, eds. Art of the North American Indians: The Thaw Collection at the Fenimore Art Museum, 2nd ed. Cooperstown, New York: Fenimore Art Museum, 2016, p. 359.

Culture

Haida

Bent-Corner Bowl

Date1780-1840

DimensionsOverall: 10 7/8 × 15 × 17 in. (27.6 × 38.1 × 43.2 cm)

Object numberT0182

Credit LineLoan from the Eugene V. and Clare E. Thaw Charitable Trust

Photograph by John Bigelow Taylor, NYC

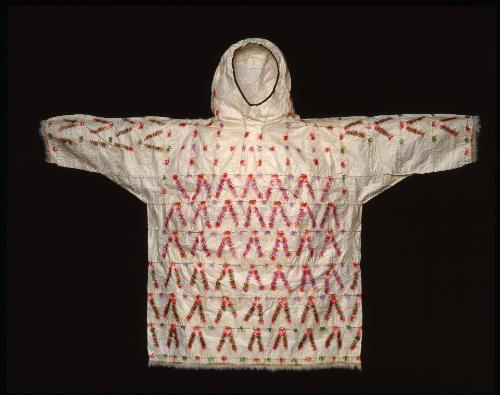

Label TextBulge-sided, bent-corner bowls or dishes are one of the most remarkable wood technologies that any culture has developed. A large container such as this one represents a respectable amount of effort and refined experience to complete the task to this degree of perfection. To create a dish with this dimension to the sides bulges requires a split plank or half-log of wood more than four inches in thickness and as long as the largest circumference of the bowl (in this case, at least five feet four inches). The four sides of the container are created from this single plank. Each side is carved to its convex forms and hollowed out on the underside to an average thickness of about three eighths of an inch. Then three special notches, called kerfs (an adaption of the British woodworking tern for a saw cut) are cut across the inside width of the plank at th epoints where the corners will be. This dish was bent using ninety-degree V-shaped kerfs, which produced tight, forty-five degree miter-type corners visible on the upper rim. This styl of kerd focuses all the stress of bending along a single line, and can sometimes fracture along the corner if the wood is not limbered sufficiently by moisture and steam. A variety of differently shaped kerfs have been devised over time, in order to distribute the strain of bending the wood fibers over more than a single point. Bowl-makers throughout the Northwest Coast have inverted and employed a wide range of different kerf types.After the carefully worked, thinned-out plank has been soaked to saturate the wood cells with moisture and steam heat has been applied to soften the lignin that binds the cells together, the plank can be bent on the three kerfs to create the four sides of the container. The fourth corner was in this case sewn with a sinew cord, the usual method in older bent containers from the early 19th century and before. An experienced carver removed the right amount of wood from just the right places so that the corners could bend efficiently and the inside of the rim could meet precisely at the corners. The interplay of dynamic curves in the shapes of the sides make this process much more challenging than the appearance of the refined finished product might suggest. (From the Catalog of the Thaw Collection of American Indian Art, 2nd ed.)

ProvenanceMorning Star Gallery, Santa Fe, New Mexico

BibliographyVincent, Gilbert et al. Art of the North American Indians: The Thaw Collection. Cooperstown, New York: Fenimore Art Museum, 2000, p.335.

Fognell, Eva and Alexander Brier Marr, eds. Art of the North American Indians: The Thaw Collection at the Fenimore Art Museum, 2nd ed. Cooperstown, New York: Fenimore Art Museum, 2016, p. 359.

On View

Not on viewc. 1915-1925

late 19th Century